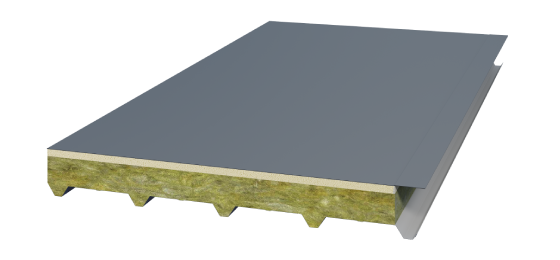

Roofs are coating covers used in structures for the purpose of providing active protection against natural conditions such as snow, rain and storms, and also vary in order to achieve aesthetic harmony with geographical conditions and building architecture. Roofs vary according to their carrier systems, slopes and coating material. Roof coating materials should provide heat, water and sound insulation, be economical, aesthetic and high quality, and at the same time, they should be able to fulfill their duties of protecting the structure safely from external atmospheric conditions. The most preferred roofing materials in roof panels are sandwich panels consisting of internal and external metal sheets and insulation cores. Sandwich panels have recently been used in our country as coating materials in roofs, facades, internal partitions or cold rooms of many structures such as construction site structures, social and industrial structures, factories and warehouses, etc. Sandwich panels stand out in architectural preferences with their high insulation properties in addition to their fast production and assembly possibilities, high carrying capacity and lightweight construction.

Assan Panel produces sandwich panels for colorful, durable, aesthetic, fast, economical and environmentally friendly solutions in roof coatings that will meet the needs of all kinds of architectural projects. Assan Panel, the most preferred brand in the sandwich panel market and aiming to provide added value in Turkey, can produce sandwich panels with different forms and metal surfaces with rich color options by using inner filling materials (PUR, PIR, Rockwool) in different thicknesses and features.

Assan Panel uses painted galvanized sheet metal rolls imported from the world's leading sheet metal manufacturers and produced in accordance with ECCA (European Coil Coating) norms or aluminum rolls produced in ASSAN Aluminum facilities in accordance with international (EN, ASTM and ISO) norms in its roof panel products. The thickness of metal trapezoidal sheets and inner filling materials is determined in accordance with the area to be used and the amount of load it will carry. Polyurethane (PUR) used as inner filling material in sandwich panels has the best heat insulation values, while Polyisocyanurate (PIR) provides high level fire and heat performance, and Rockwool provides successful results in fire and sound insulation.

Assan Panel Sandwich Roof Panel products are manufactured as Capped, Lateral Lapped, PVC / TPO Membrane and are designed to meet all kinds of requirements.

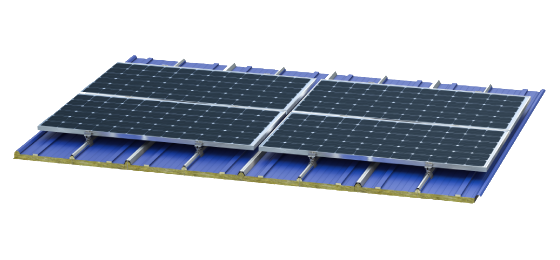

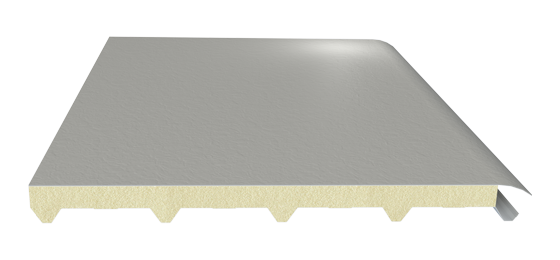

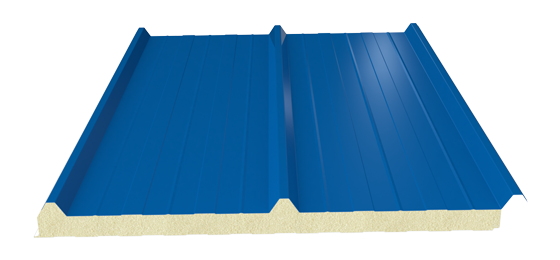

Master Panel 1000R4 is the first, only and real capped sandwich roof panel manufactured in Turkey and its biggest advantage is that the panel connection elements are protected from external factors thanks to a cap profile covering the panel joint point.

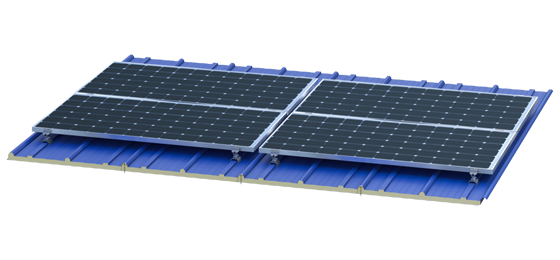

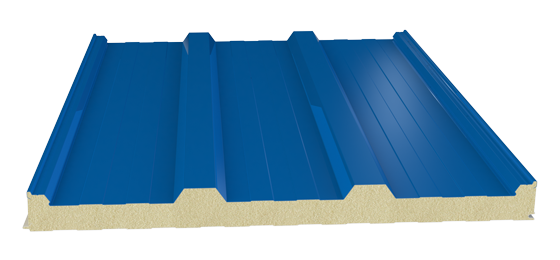

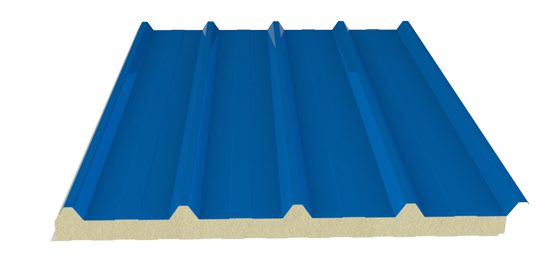

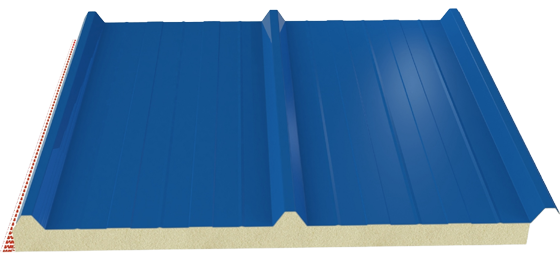

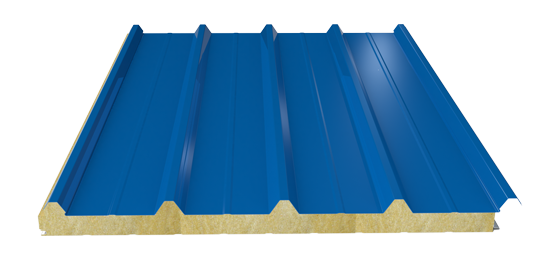

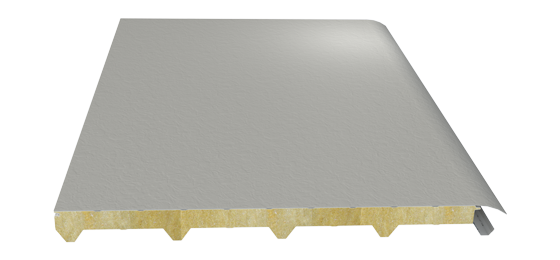

Master Panel Nova3 is a three-ribbed, Nova5 and five-ribbed side-lapped sandwich roof panel. Roof coverings can be made with 10% slope with Lateral Lapped Panels and their biggest advantage is that they can be quickly installed thanks to the side-lapped panel connection. Master Panel N5TM is used in terrace roof coverings. The lower surface of the panel is metal (painted galvanized sheet) and the upper surface is produced with membrane. Thus, there is no need to coat the construction site with water insulation material after assembly, saving time and labor.

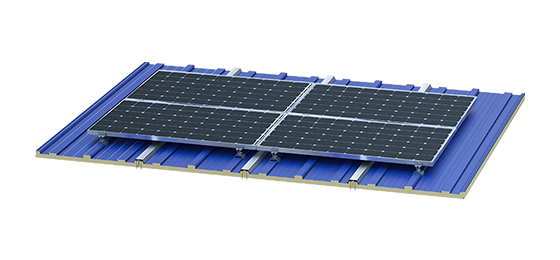

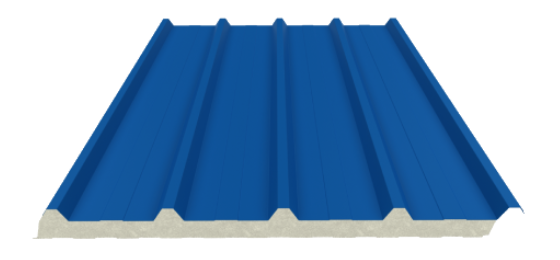

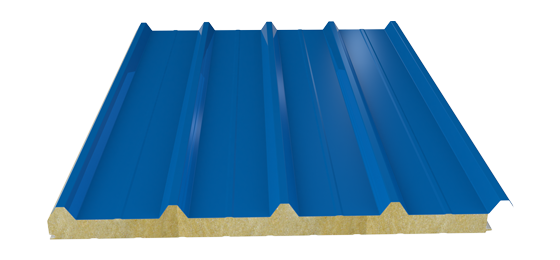

Master Panel 1000R5T is used safely in buildings with high fire risk and in buildings where maximum fire resistance is required, while its five-ribbed form ensures that wide openings can be safely crossed. Roof cladding can be done with a 10% slope. It provides an advantage in fast assembly thanks to its side-lapped panel connection. It offers high acoustic performance thanks to its rockwool inner filling material.